50pcs Solder Seal Wire Connector Kit

- Easy to identify and operate - Different colors correspond to different sizes, easy to pick up for use. A transparent sleeve provides precise inspection when stripping and inserting wires inside.

- More Effective Way -1 Step solder and seal process for all your connections, insulated and sealed.

- Waterproof: Unique double-wall design, external polyolefin pipe, built-in hot melt adhesive. When heated, the polyolefin tube shrinks in size, and the adhesive flows through the insulation. Double-wall tubing ensures a watertight seal to prevent wire corrosion

- No-Slip Wire Contact - Tubing reduces in size and solder will melt and flow through the stripped wires, ensuring strong holding --- your wire will never slip out of the connector. Can be ideally used in marine and automobile applications

- Package include: 50 pcs Solder Seal Wire Connector, 23 pcs Red, 12pcs Blue, 10pcs White, 5 pcs Yellow

Waterproof Solder Seal Wire Connectors

Features

- Shrinkage Ratio 2:1.

- An Easy One-Step Wire Connections.

- Easy Identification: Color-coded connector tubing.

- Polyolefin heat shrink butt connectors improved pullout strength.

- High-quality wire connectors in Seal, Strain Relief, Cable Chick, and Insulation.

- Melted solder ensures wires are strongly connected and avoids wires slipping out from the terminal.

- Red Connectors: 23pcs

- Blue Connectors:12pcs

- White Connectors: 10pcs

- Yellow Connectors: 5 pcs

- Item Weight: 1.6 ounces

- Product Dimensions: 4.13 x 2.76 x 0.98 inches

Specification

Waterproof

Solder and hot melt adhesive inside can be perfectly Waterproof. The connectors can prevent wires from corrosion. The transparent sleeve of the butt connectors provides Visual Inspection. --- You can control the operating temperature and heating time.

Shrinking Ratio: 2:1

Comply with all relevant European standards; Shrinking ratio: 2:1. Durable Nylon + Brass; 3 colors (Red+Blue+Yellow)make it easy to identify the right side of the connector. Prevents the wire from shorting out, a perfect connection for the wire.

Apply Heat

Apply heat while continuously rotating the wire to make the connector evenly heated.

Minimum Shrink Temperature: 80℃.

Minimum Temperature for Solder to Melt:138℃.

How to use

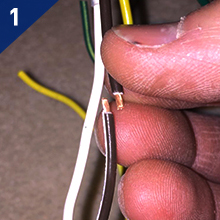

Prepare the electric wires

Put the two ends of the wire which was stripped off together and twist them.

Insert the 2 wires into the connector

Move the connector to the middle of the two-wire, align the tin ring to the uncovered wire.

Apply heat

Use a heat air gun until it is melted in size and the adhesive flows, filling gaps within the terminal.

No crimping required

No crimping is needed, very easy to use!